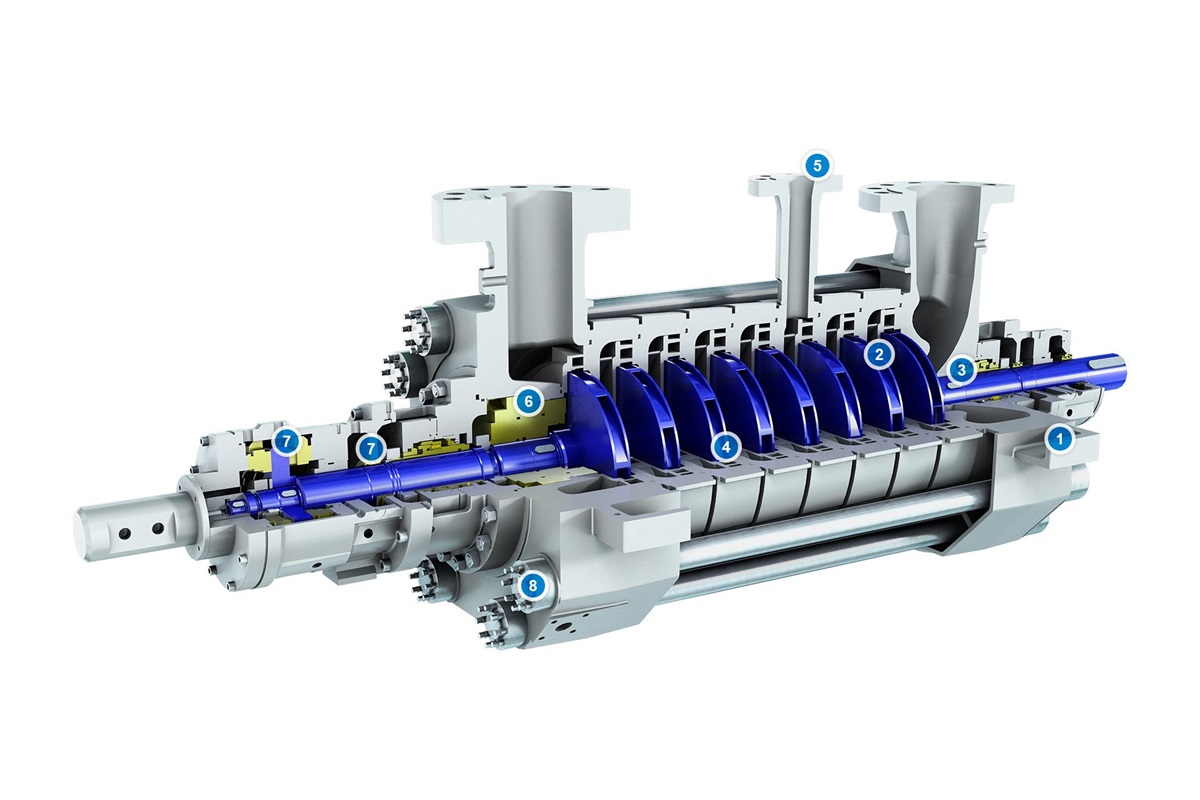

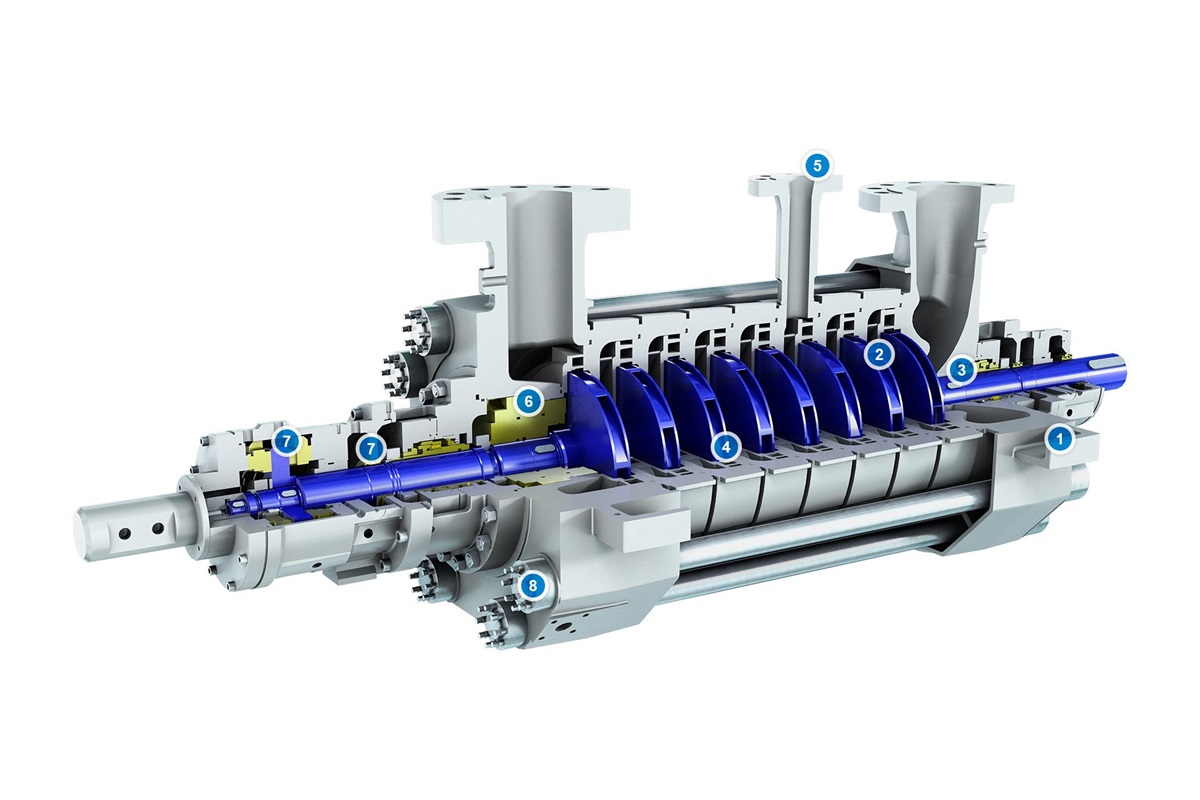

MD high-pressure stage casing pump

- Modular hydraulics for high efficiency in a wide range of operating conditions as required for gas-fired combined-cycle power plants

- Optimized design for thermal conditions as applicable in gas-fired combined-cycle power plants

- Centerline mounted with large branch sizes for optimized inlet flow, low noise level, and higher allowable forces and moments

- Unaffected by rapid temperature variations and therewith highly suitable for gas-fired combined-cycle power plants where frequent start-stop operation is specified

- Stiff shaft design for critical speeds above the maximum operating speed

- Multiple screws mechanical tensioners are used on large sizes to allow simpler tightening and loosening

The MD pumps are suitable for pumping clean or slightly polluted, hot or cold water. They have been specifically designed for application such as:

- Main boiler feedwater pump in captive, independent, biomass, and industrial power plants

- Main feedwater pump in gas-fired combined-cycle and concentrated solar power plants

- Start-up boiler feedwater pump in utility thermal power plants

- High-pressure water pump in general industry

1. Casing support

1. Casing support

Centerline mounting absorbs high forces and moments. Pre-warming not required

2. Impeller

- Several hydraulic sets per pump size guarantee high efficiencies and low operating costs over a wide operating range

- Low Net Positive Suction Head Required (NPSHR) first stage; double suction first stage can be provided for selected sizes

3. Shaft

Transmits the required torque and minimizes deflection

4. Rotor design

Stacked rotor with staggered keyways to transmit torque

5. Intermediate take-off

Reduces head losses; large take-off flow is available on certain sizes

|

50 Hz |

60 Hz |

| Discharge sizes |

up to 200 mm |

up to 8 in |

| Capacities |

up to 1,200 m3/h |

up to 5,300 US gpm |

| Heads |

up to 2,800 m |

up to 9,200 ft |

| Suction pressures |

up to 50 bar |

up to 725 psi |

| Discharge pressures |

up to 350 bar |

up to 5,080 psi |

| Temperatures |

up to 210°C* |

up to 410°F* |

| Pump part |

Material |

| Suction stage and discharge casings |

Chrome steel |

| Impellers |

Chrome steel |

| Shaft |

Chrome steel |

| Balancing system |

Chrome steel |

1. Casing support

1. Casing support